Scalable, Flexible Electronics for Your

Toughest Electromechanical Problems

How is Our

Product Different?

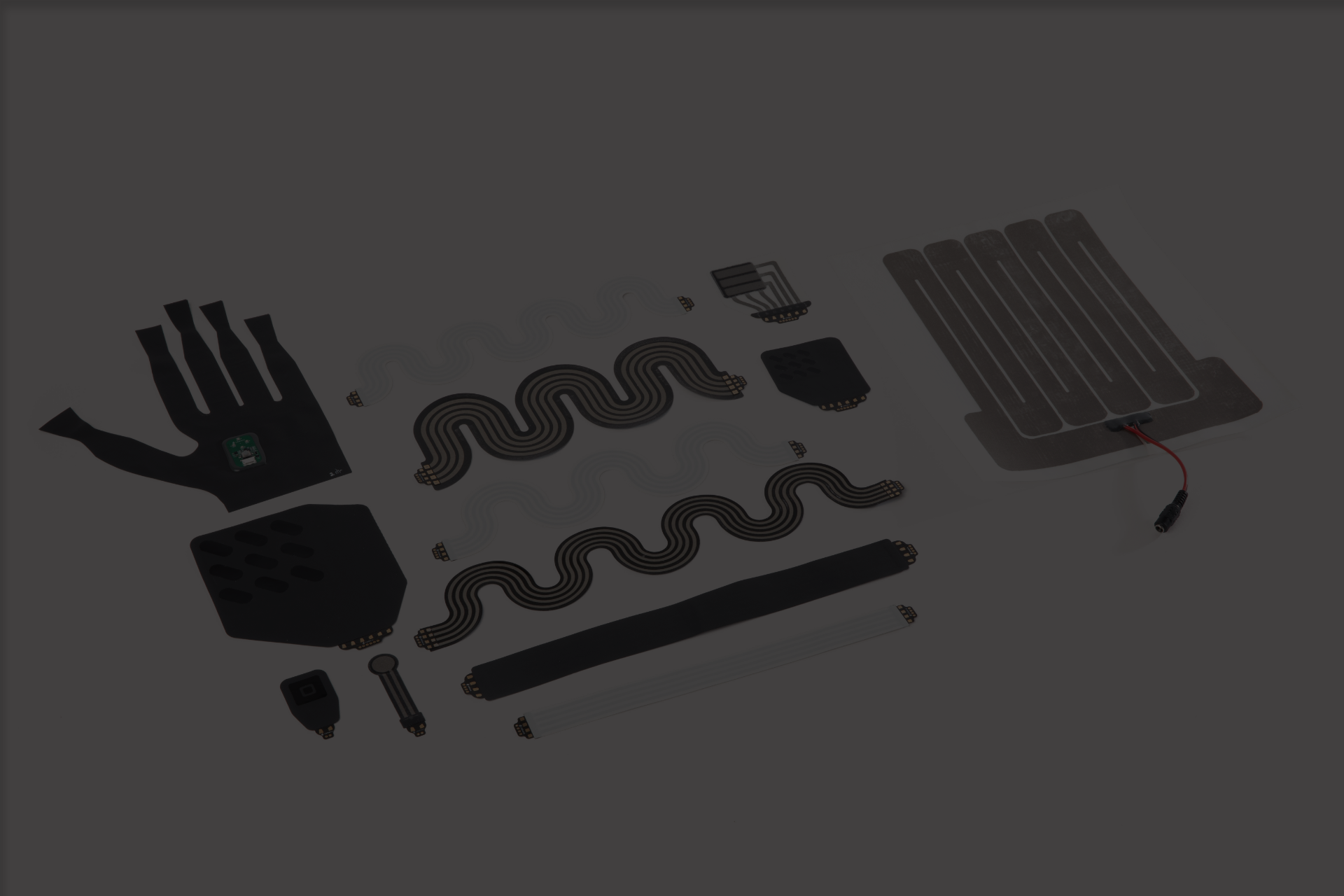

The LOOMIA Electronic Layer (LEL) is an award-winning e-textile circuit that can operate where normal circuit boards cannot. We provide a scalable circuitry solution with multi-axis flex to companies looking to develop electronics for high-motion areas. Three years of research, resourcing Stanford Nano Shared Facilities for analysis and characterization, went into developing our LEL technology.

About the LEL

The Loomia Electronic Layer is a soft, flexible circuit that can enable next-generation products in wearables, automotive, and beyond. Our technology can cost as little as $0.05 per square inch.

How Are We

Different?

More Drapable than

Flex PCBs

The LEL is more drapable than flex PCBs, wires on mesh, or most other flexible electronics options. We have a similar flexibility to printed ink on TPU. However, because our technology is not printed, it allows us to design low-resistance conductors that do not easily change resistance when stretched.

Combining

Functionalities

The LEL can also be used to combine functionalities such as heating, switching, and lighting all into one component that directly integrates into a surface textile or material of your choice.

No Need for

Plastic Housing

Unlike most other circuit technologies, our electronics are designed to integrate into products without the need for a plastic housing.

Scalable up to

20,000 Units a Week

Our partner, Eastprint, can produce as many as 20,000 LEL units a week in an ISO 9001- and ISO 13485-certified facility. We source our materials from reputable brands, ensuring that we can reach scaled production when necessary.

Our patented technology

focuses on the following characteristics:

Lightweight and Flexible Form Factor

1.

We take a flat and drapable approach to circuitry that can be patterned to be 4.15 to 340 times lighter than a hard wire equivalent for power and data buses. Our drapable system can be designed to work in collaboration with wires or be completely wire-free to strike the perfect balance between cost and performance.

Performance

2.

The LEL is customized to provide higher performance. Our comparative testing shows higher heating efficiency and lower current pull than existing automotive solutions. We also show 40% higher antenna performance than conductive ink on TPU equivalents for healthcare and wellness.

Hard-Soft Barrier Connection

3.

The hard-soft interface is a challenge for our industry. When integrating a component into an e-textile, the hard-soft challenge must be overcome to ensure that zone does not break when stressed, nor have a higher resistance than the rest of the assembly. Our patented technology provides a robust, reliable, and efficient connection between hard and soft components.

Modularity

4.

The LEL consists of 5 main components: the soft layer, the interconnect, integrated components, adaptor cable, and power source. Through our modular approach, all of these components are individually customizable as well as replaceable by a component of our customers’ choice. This gives us flexibility in integrating any SMD sensor or additional technologies into our system.

Customization

5.

LOOMIA’s patented patterning and assembly method allows us to customize the functionality, size, and shape of the layer, position of intended functionality areas, and the insulation method for the environmental conditions of the use case. Through the versatile nature of our patterning method, we can design for small surface area (small pitch) as well as very large surface area applications with optimized energy efficiency.

Integration

6.

Wired systems can be hard to integrate.

LOOMIA creates an entirely wire-free system to facilitate easier electronic integration into soft goods products. The LEL is sewable and bondable to accommodate easy integration. It is also pre-cut, so there is no risk of damaging the circuit.

We are

trusted by

engineers at

big and small companies alike.

Automotive

For automotive OEMs and interior suppliers, LOOMIA can offer high performance in three categories:

Seat Heating

Steering Wheel Heating

Smart Surfaces / HMI

We collaborate with each company to customize our heaters and user interfaces to satisfy their current, voltage, and form factor needs, which in turn ensures easy integration.

Can scale up to 20,000 units per week in an ISO 9001 facility

Seat and Steering Wheel Heaters can get up to 93.33°C and can be designed to pull less current than existing market options

Cabin Lighting can be used in headliners for ambient effects

Soft User Interfaces can be implemented throughout the vehicle

Passed environmental testing from -20°C to 85°C

Product Offering: Seat and Steering Wheel Heating, Cabin Lighting, Soft User Interfaces

Outdoor Products

For outdoor goods brands, LOOMIA’s LEL can add the following functionalities:

Garment and Accessory Heating

Garment and Accessory Lighting

Unlike wire-based heating and lighting systems, the LEL is fully customizable and has a sleek form factor. These factors enable a seamless heating or lighting integration into higher-end skiing, snowboarding, and hiking gear. For high visibility applications, the LEL can add a layer of safety to running and biking products.

Product Offering: Heating and Lighting

Can be designed to optimize for breathability

Tests Conducted: AATCC 135 Washability Modified, Bleach Colorfastness, Crocking

Flat and flexible lighting at around 40 lumens for visibility. Can be integrated in tents, sleeping bags, and apparel

Flat and wire-free heating for outdoor activities. Easy to integrate into jackets, gloves, and shoes

Medical/Wellness Products

For medical/wellness soft goods products, we help teams go from flex PCB or hard prototype to a soft and wearable product. Our technology can connect pre-existing modules and pucks, allowing high technical functionality to be integrated into a soft form factor. Our low resistance conductor (.03 ohms/square) makes for highly efficient antenna translation and high-speed cabling within a soft good.

Power and Data Buses

Antennae

Sensor Integration

Functionalities

Tests Conducted: AATCC 135 Washability

Can scale up to 20,000 units per week in an ISO 13485 facility for production

Our LEL outer is made from biocompatible TPU

Can design the LEL to incorporate breathability zones

Our proprietary hard-soft connections allow us to connect the LEL to USB, JST, or any other off-the-shelf connectors